The world’s first 3D-printed steel pedestrian bridge was opened on the Oudezijds Achterburgwal canal in the city of Amsterdam on July 15, 2021. Máxima, the Queen of the Netherlands attended the opening ceremony of the bridge.

“A 3D-printed metal structure large and strong enough to handle pedestrian traffic has never been constructed before,” said Professor Leroy Gardner, Department of Civil and Environmental Engineering, Imperial College London. 3D printing presents tremendous opportunities to the construction industry, he further added.

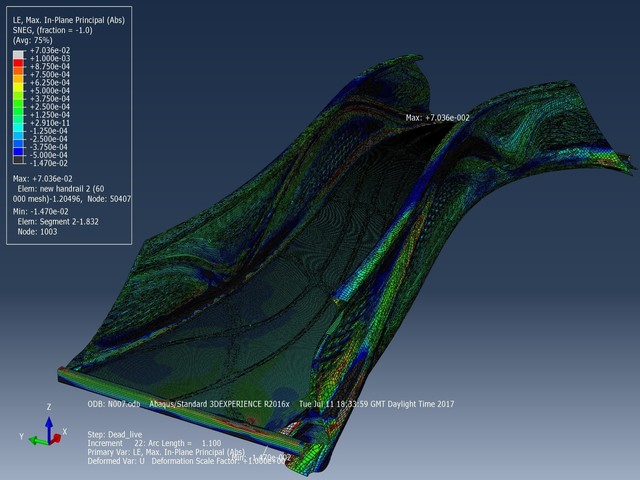

Dr Craig Buchanan, Department of Civil and Environmental Engineering, Imperial College London said for over four years, they have been studying the printed microstructure, with load testing on the completed bridge.

The world's first 3D-printed steel bridge opens in Amsterdam!🤩🌉 Co-developed by our engineers @ImperialCiveng and @MX3D_AM, the bridge is over four years in the making and was unveiled by Her Majesty Queen Máxima of the Netherlands. https://t.co/JL6S23UATI

— Imperial College (@imperialcollege) July 15, 2021

About the 3D-printed steel bridge

•The bridge named the MX3D Smart Bridge has been created by Dutch company MX3D using a 3D printing technique called wire and arc additive manufacturing. The technique combines robotics with welding.

•The 6-ton stainless steel bridge measuring 12-meter (40-foot) is installed with sensors that will aid researchers at the Imperial College London in measuring, monitoring, and analyzing the performance of the bridge at how it handles pedestrian traffic.

•The bridge will remain in place for two years. The data collected will aid engineers and researchers in measuring the real-time ‘health’ of the bridge and exploring how the public interacts with 3D-printed infrastructure.

•The Imperial researchers are a part of a team comprising statisticians, computer scientists, mathematicians, and structural engineers who are working on the Alan Turing Institute-Lloyd’s Register Foundation programme.

•The Alan Turing Institute along with the Engineering and Physical Sciences Research Council has funded the team.

•The Joris Laarman Lab came up with the initial designs of the bridge.

World’s first 3D-printed bridge: How will they study data?

•The data collected from the sensors will be applied to a computerized ‘digital twin’ version of the bridge.

•The real-time performance and behavior of the physical bridge against the twin version. This will help to assess the long-term behavior of 3D-printed steel.

Comments

All Comments (0)

Join the conversation